Innovative thinking, top quality and an exceptional range of products, fast reaction times and continuous technical development have made ewo what it is today: a trademark for compressed air and oxyfuel fittings worldwide.

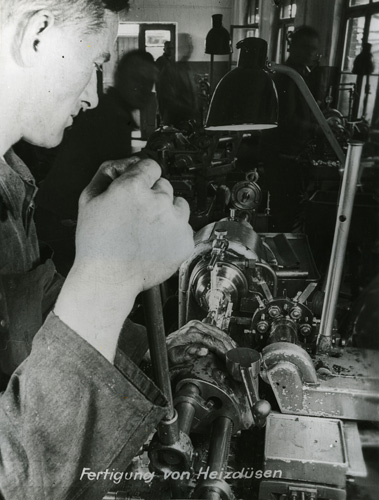

Our developments, based on customer-specific requirements in practice, especially in the field of compressed air preparation, document our competence also for individual solutions with a system. Our air service equipment of proven quality, reliability, operational safety and precision is appreciated by service stations and automotive workshops alike.

Our product range is divided into four major product groups or product areas, which are interrelated in many areas of application. There are also synergy effects in development and production, which we use in the interest of our customers.

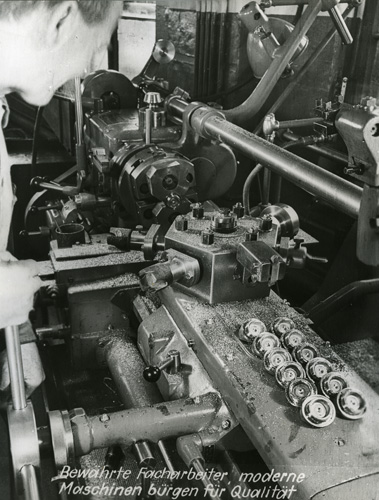

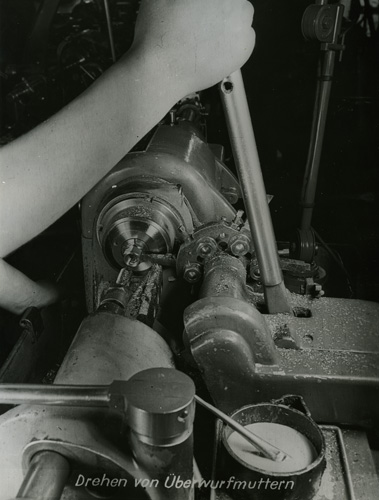

Swabian thoroughness and perfection